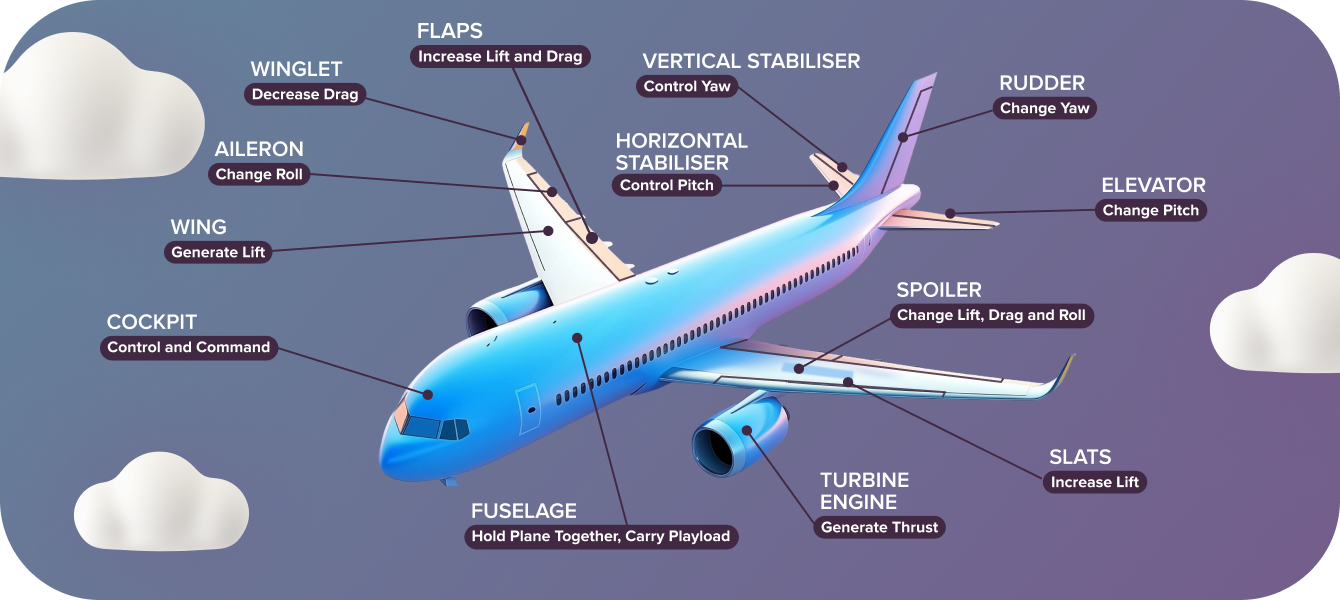

From Nose to Tail: Aircraft Parts and Their Functions

As a student pilot, one of the first lessons you'll dive into is understanding the different sections of an aircraft. From the navigation display in the cockpit to the intricate design of the wing structure, knowing how each part works is essential for success in the aviation industry.

An aeroplane comprises several key sections: the fuselage, wings, cockpit, engine, propeller, tail assembly, and landing gear. Each plays a vital role, and learning how they interact is your first step toward mastering the principles of aerodynamics. Let’s build your knowledge and confidence, one section at a time!

Discover key subtopics and core concepts of Aircraft General Knowledge explored here.

The Backbone of an Aircraft

The airframe forms the structural foundation of an aeroplane, ensuring it can withstand aerodynamic forces and support various systems and components. The structure of an aeroplane can be decomposed into five main sub-assemblies: the fuselage, wings, empennage, flight controls, and landing gear.

The Fuselage: The central body structure accommodates the cockpit, passengers, and cargo. It also connects other components such as wings and the empennage.

The Wings: The primary lift-generating surfaces have control surfaces such as ailerons, flaps, and slats.

The Empennage (Tail Section): Comprises stabilisers and control surfaces that ensure stability and control around the pitch and yaw axes.

The Landing Gear: The undercarriage of an aircraft, designed to support the aircraft on the ground during taxiing, take-off, and landing.

Control Surfaces: Enable the pilot to manoeuvre the aircraft by altering its orientation around its axes.

Practise Aircraft General Knowledge questions by clicking here

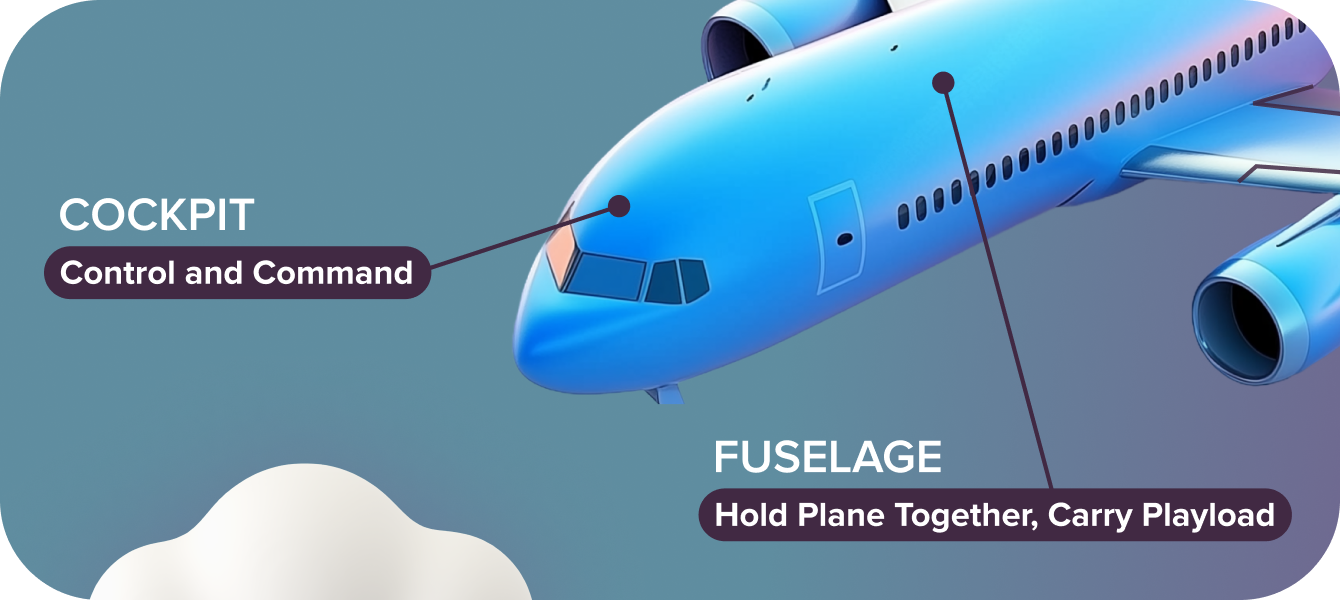

Fuselage

The heart of any aeroplane is its fuselage — a long, sturdy metal tube that connects all the main components of the aircraft. Beyond just holding things together, the fuselage is designed to protect the flight crew, passengers, and cargo, even as it withstands the intense changes in atmospheric pressure during flight.

At the front and centre of the fuselage lies one of the most recognised parts of an aeroplane: the cockpit, or flight deck. Nestled just above the aircraft’s nose, this is where pilots take command, navigating the plane forward using advanced electronic flight instruments. These instruments, displayed on the primary flight display, form part of what’s known as a “glass cockpit.”

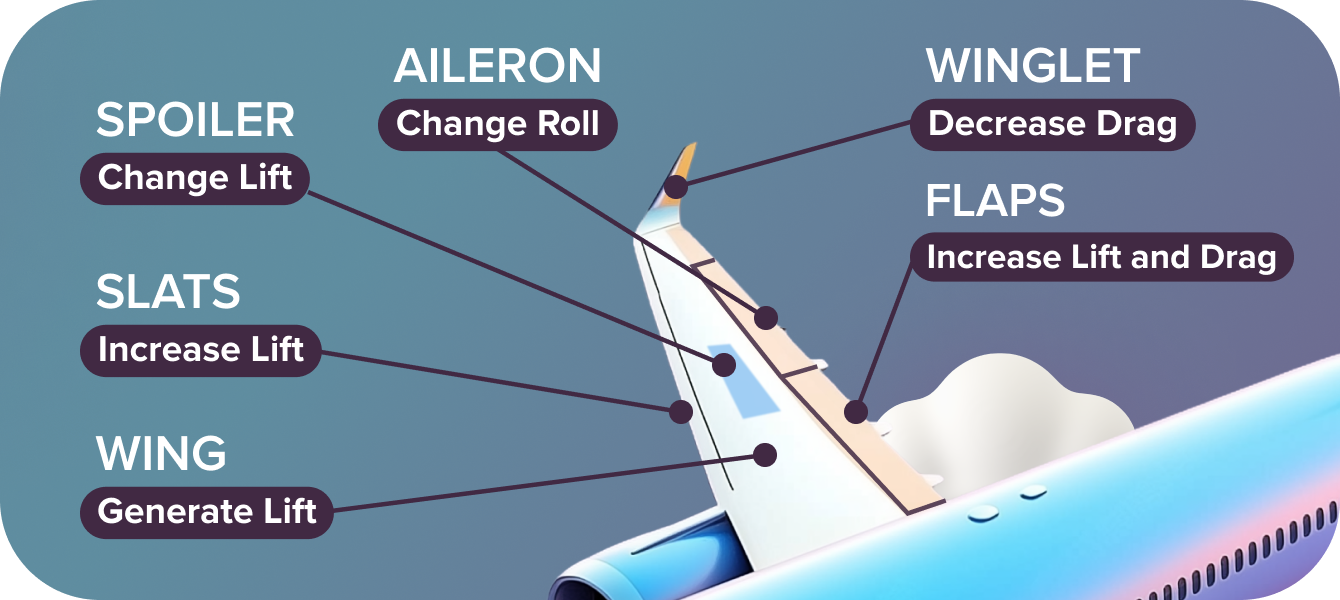

Wings

Wings are aerodynamic structures attached to the fuselage that generate lift. They house control surfaces like ailerons, flaps, and slats. The wings are the unsung heroes in this process, generating the majority of the lift that holds the plane aloft. However, creating lift isn’t as simple as it sounds — aeroplanes must be pushed through the air to achieve it. This movement encounters resistance in the form of aerodynamic drag, a challenge modern airliners tackle with winglets, the small extensions at the wingtips that reduce drag and improve efficiency.

Here are the key components that make wings so effective:

Wing Root: The part of the wing closest to the fuselage, providing structural stability.

Wing Ribs: Internal supports that shape the wing and distribute loads evenly across its surface. Together with spars, ribs ensure the wing can handle aerodynamic forces.

Ailerons

Hinged surfaces on the trailing edge of the wings, near the tips, control the aeroplane’s roll and allow it to bank left or right. When one aileron rises, the opposite aileron lowers, creating differential lift on the wings and rolling the aircraft. Fun fact: the term “aileron” comes from the French word for “little wing”!

Wing Flaps

Extendable surfaces on the trailing edge of the wings are designed to increase lift and drag during take-off and landing. Thanks to flaps, an aircraft can maintain controlled flight at significantly slower speeds, preventing the wing from stalling. Flaps extend downward to increase the wing’s surface area and camber. This enhances lift at low speeds, which is especially crucial during short-field operations or steep approaches.

Slats

Movable surfaces on the leading edge of the wings increase lift by optimising airflow over the wing during take-off and landing. Slats slide forward during takeoff and landing, creating a gap between the wing and the slat. This gap channels airflow smoothly over the upper surface of the wing, delaying airflow separation and reducing the risk of a stall.

Slats are particularly valuable in achieving low-speed flight without compromising lift, making them crucial during the approach and landing phases. On some aircraft, slats are automatically deployed based on the angle of attack.

Spoilers

Panels on the upper wing surface, that reduce lift and increase drag, are used during descent and landing. Spoilers are deployed upward into the airflow, disrupting the smooth flow over the wing. This reduces lift and helps in controlled descents or braking during landing.

Winglets

Vertical or angled extensions at the wing tips that reduce drag caused by wingtip vortices. They improve fuel efficiency, making them essential for reducing costs and environmental impact in modern airliners.

Empennage

The empennage, or tail assembly, is more than just the “back end” of an aeroplane—it’s the foundation of stability and control during flight.

While the wings generate lift and the engines provide thrust, the empennage works tirelessly to keep the aircraft balanced and aligned, countering the rotational effects of airflow (or relative wind).

The tail assembly includes the horizontal stabiliser, vertical stabiliser, elevator, and rudder, along with several other features that contribute to stability and control. It also houses the tail number, the unique identifier for each aircraft. Additionally, static wicks—small conductive devices on the trailing edge—dissipate static electricity that builds up during flight, protecting the aeroplane’s systems.

Horizontal Stabiliser

A fixed surface in the empennage that provides longitudinal stability and supports the elevators. Prevents the aeroplane's nose from moving up and down (pitch). This fixed horizontal surface balances the aircraft's centre of gravity, maintaining a level flight path.

Vertical Stabiliser

A fixed tail structure provides directional stability, to which the rudder is attached. Prevents the aeroplane’s nose from swinging side to side (yaw). This fixed vertical surface keeps the aircraft aligned with its intended flight path, acting like a keel on a boat.

Fun Fact: On the Wright brothers’ first aircraft, the horizontal stabiliser was placed at the front of the plane. This configuration called a canard (French for “duck”), is still used on some modern aircraft designs.

While the stabilisers provide fixed stability, the elevator and rudder — the hinged, movable parts of the stabilisers—are essential for controlling and manoeuvring the aircraft:

Elevator

Located on the horizontal stabiliser, these control surfaces manage pitch (the up-and-down motion of the nose), raising or lowering the aircraft's nose. When the elevator deflects upward, it decreases lift on the tail, causing the nose to pitch up. When it deflects downward, it increases lift on the tail, causing the nose to pitch down.

Rudder

A vertical control surface on the tail is used to control the yaw (the side-to-side motion of the nose), helping steer the aircraft left or right around its vertical axis. Deflecting the rudder to the left or right changes the airflow over the tail, causing the aircraft to yaw in that direction.

Together, the elevator and rudder allow precise adjustments to the aircraft’s flight path, ensuring smooth and stable navigation.

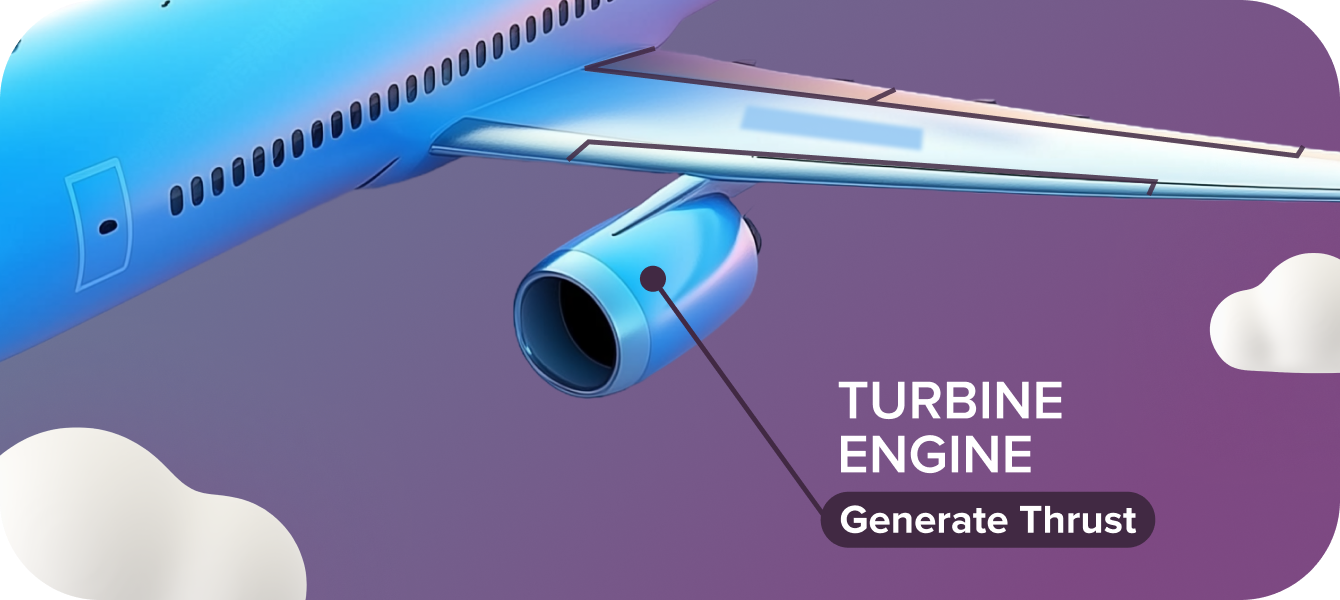

Turbine Engines

To push the aeroplane forward and overcome drag, most modern aircraft rely on turbine engines mounted beneath the wings, providing the thrust needed for propulsion. On smaller, low-speed planes, propellers are often used instead of turbines, offering a simpler solution for generating thrust. While the engine itself is not part of the airframe, its integration is critical to the aircraft’s overall performance. Turbine engines are mounted on pylons beneath the wings or integrated into the fuselage. The airframe is designed to absorb engine vibrations and stresses while maintaining aerodynamic efficiency.

Types of Turbine Engines:

Turbojet: Produces thrust solely from jet exhaust.

Turbofan: Features a fan to bypass air around the engine core, enhancing efficiency.

Turboprop: Uses a turbine to drive a propeller, combining jet and propeller technologies.

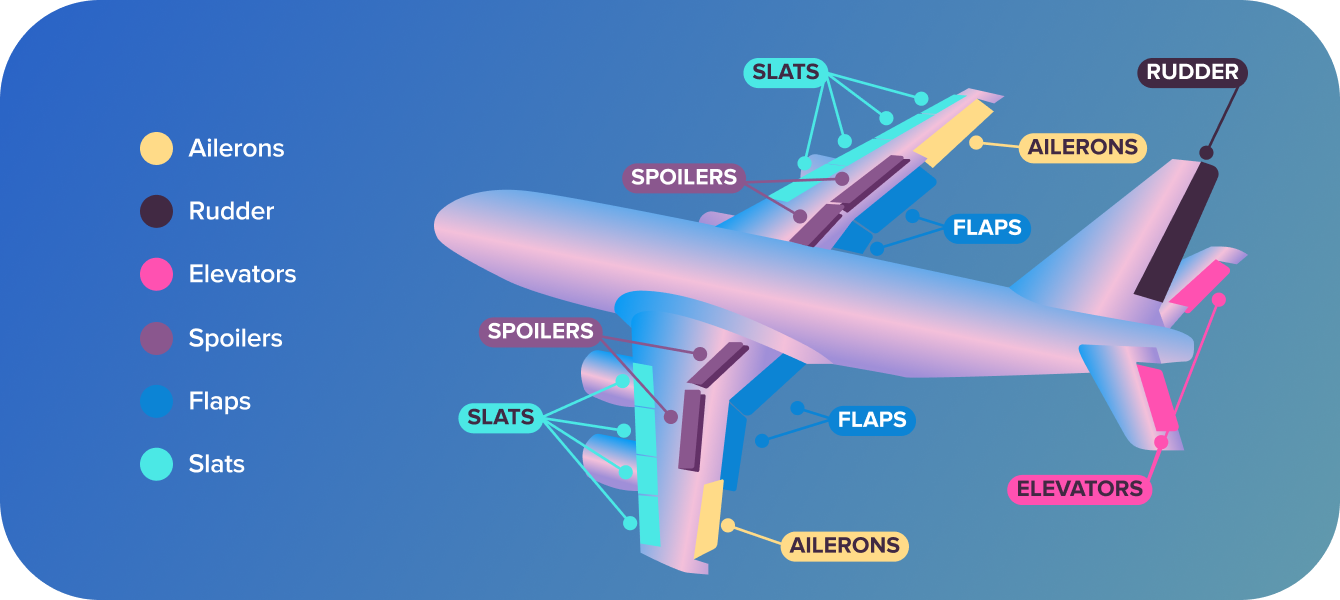

Aeroplane Control Surfaces

In the picture below, you can see all the aeroplane control surfaces, including ailerons, elevators, rudder, spoilers, slats, and flaps. The control surfaces are seamlessly connected to the cockpit through mechanical linkages, hydraulics, or electrical systems. Without the structural support of the wings, fuselage, and empennage, these surfaces would lack the necessary foundation to perform their functions.

Control surfaces allow pilots to manoeuvre the aircraft by influencing its movement around the three axes of flight:

Roll: Rotation around the longitudinal axis, controlled by the ailerons.

Pitch: Rotation around the lateral axis, controlled by the elevators.

Yaw: Rotation around the vertical axis, controlled by the rudder.

Airhead's Takeaway

An aeroplane’s anatomy is a masterpiece of design, with each part working harmoniously to achieve the miracle of flight. The control surfaces, in particular, showcase the perfect balance of stability and manoeuvrability, allowing pilots to navigate the skies with precision.

As you deepen your understanding of these systems and how they connect to the larger airframe, you’ll not only appreciate the complexity of aviation but also build the knowledge and skills required to master it. Whether you’re commanding the cockpit or studying aerodynamics, remember that every flight is a symphony of coordinated parts—all working together to defy gravity and soar.